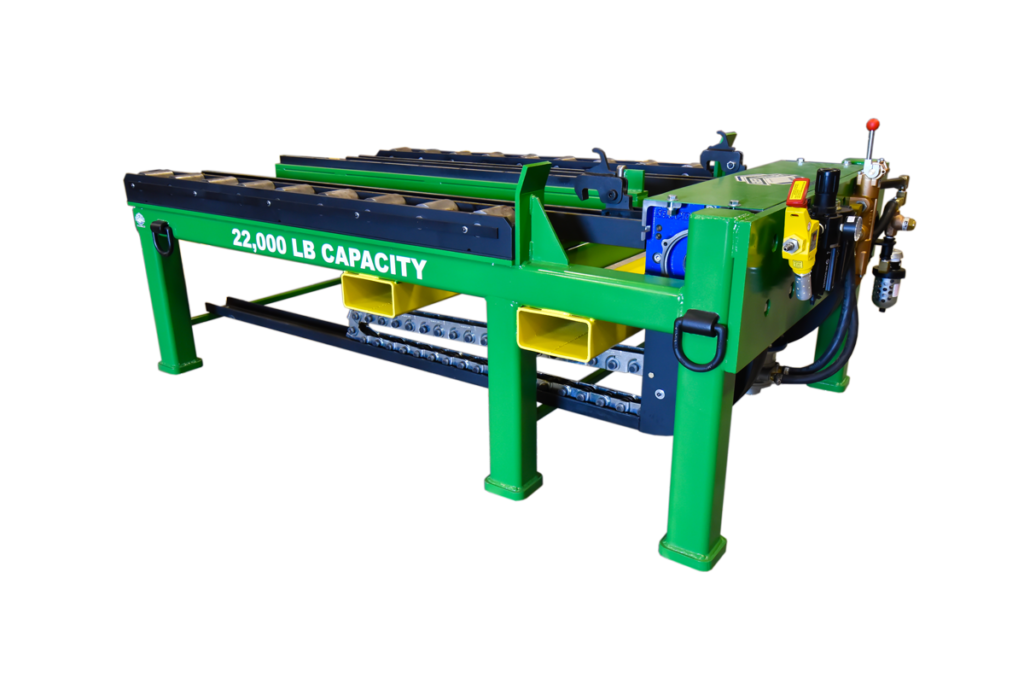

FEATURES

- Pneumatic powered rigid chain push/pull transfer system with custom grippers

- Gravity rollers to assist transfer

- Fork pockets to transfer table to press or storage

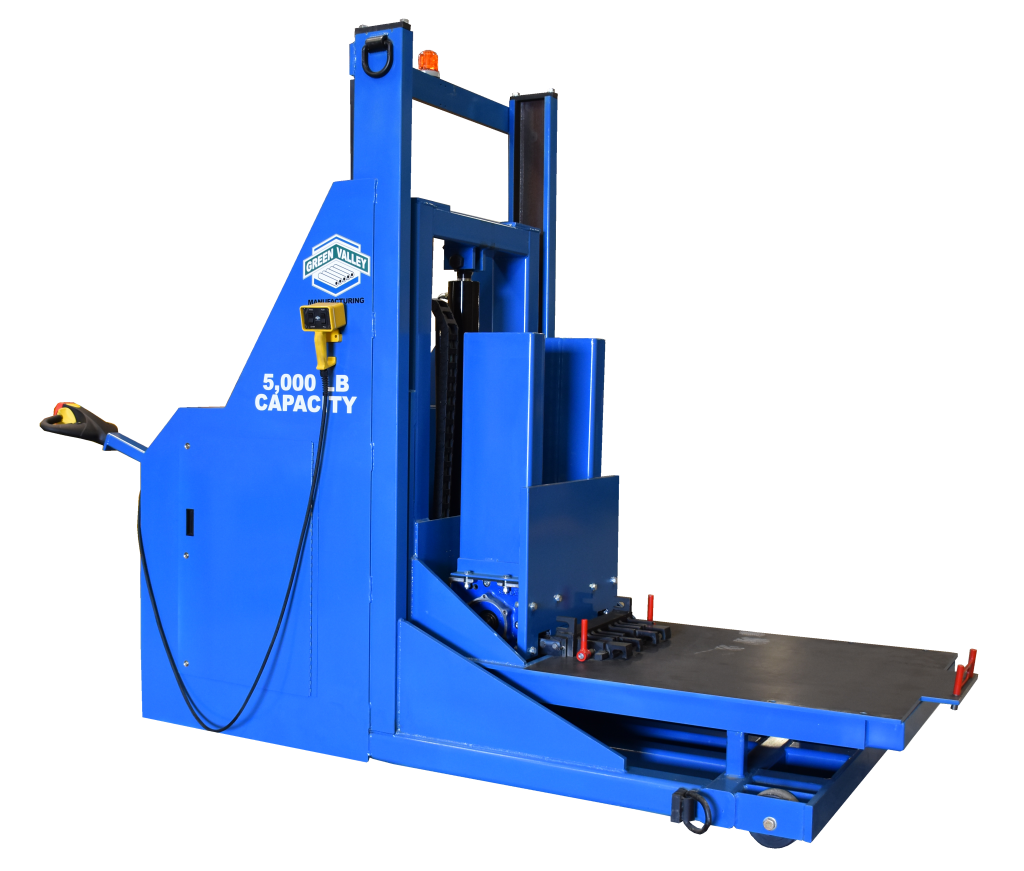

CART CONTROL – Tiller head control system

DECK TRANSFER – Rigid Chain push/pull wiper bar

Deck comes with mold locater blocks to align mold & various mold gripper sizes

DOCKING – Docking guides and pins

TOP SURFACE – Steel

COLOR – Green Valley Gold

SAFETY – Visual Strobe Lights, Emergency Belly Stop

CART CONTROL – Tiller head control system

DECK TRANSFER – Rigid Chain push/pull with custom gripper extends 24″ into press or storage.

DOCKING – Side guides align with rails for easy press or storage alignment.

DECK – Hydraulic style scissor lift eck for maximum strength and height range.

TOP SURFACE – Low Friction Gravity Rollers

COLOR – Green Valley Gold

SAFETY – Visual Strobe Lights, Emergency Belly Stop, Die Stop, Safety Laser Scanners for collision avoidance and precision docking, Front gate sensor locks down the cart when not in place.

This heavy duty die transfer cart is custom built & packed with features. Quick die transfers have never been more efficient with a rail guide system allowing for proper alignment at the press or storage. This powerful mold cart has a scissor lift style deck for a total capacity of 7,000 lbs.. A serapid driven push/pull system drives the die transfer while multiple stop gates keep the tool secure during transport. A safety sensor on the front stop gate ensures that the die cart is secured before the drive is enabled.

Green Valley Manufacturing heavy duty die transfer carts have a history of creating safer & more efficient manufacturing environments. The use of die carts is proven to create a quick die change environment that can reduce tool changes by up to 70%. (Fabricator Magazine)

Mold Cart:

Mold Cart:

• Touchscreen HMI with deck readouts, wheel readouts, & precision deck control

• 75” deck raise heigh

• Docking Lasers for precision deck control

• Joystick throttle w/ enable grip & horn

• Front & rear precision rack sensors

• Powered bolster extensions for transfer

• Independently controlled die grippers

• Single station powered mold cart with variable height deck

• Powered push/pull system for mold transfers to/from presses and racks

• Powered drive via ergonomic tiller handle

• Dual rigid-chain push/pull system for single stroke powered mold transfers

• Heat shield between push/pull gripper and push/pull drive