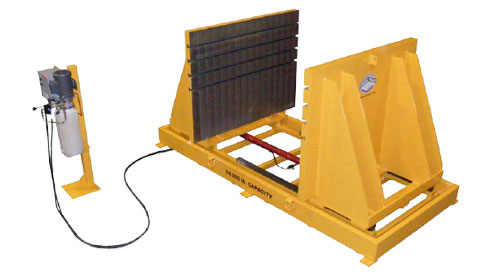

Green Valley Manufacturing produces a range of high capacity upenders designed specifically to meet the needs of our client’s coil handling or material handling applications. Our line of upender or tipper products is custom built to last and handle any sized capacity. Custom designed to meet the needs of your application the Green Valley Manufacturing upender is a safety conscious and money saving edition to any coil handling or material handling process.

Upenders-Tippers-Splitters

What is an upender or tipper

An upender or tipper is used in a variety of applications and is a great alternative to a weld positioner. They are typically used in servicing injection molds to lay the mold down for an overhead crane to split them vertically. It’s also used in upending coils to allow handling via a c-hook through the coil ID. Their primary function is to upend or downend a load to a 90-degree angle. This makes changing positions to transport or service the load far more efficient. Tippers or upenders are easy to integrate with any material handling system.

Industries That Use a 90º Upender or Mechanical Tipper

An upender is used to safely rotate a load 90 degrees. They’re used in a number different industries including:

- Automotive

- Manufacturing

- Die Splitter w/ 180º rotation

- Coil handling

- Injection Mold Maintenance

- Forging applications

- Industry dealing with steel or aluminum

Green Valley Manufacturing’s upender line is designed to turn wide stacks of products or extremely heavy loads including coils, molds, and more. Industries that work with steel, aluminum and other heavy materials can benefit from mechanical tippers and upenders, as they protect workers and improve efficiency.

An upender is an important addition to any factory floor. You can easily tip steel, aluminum and other types of coils or molds using this equipment. Your employees won’t have to handle any loads, helping you avoid workplace accidents, tool damage, time off and compensation claims.

A Safer Way to Handle Heavy Loads

The main benefit of using a coil tipper or upender is safety. Working with any heavy load introduces the potential accidents or injuries. With an upender, staff doesn’t have to turn loads manually or using unsafe means. This results in less chance of an accident — which can interrupt your productivity, damage your products, coils, and molds, or lead to costly liability issues. Our equipment features easy-to-use motorized controls that can be automated for increased convenience.

Streamline Your Workflow with a Coil Upender

Upenders and 90 degree tippers can do the work of upending a pallet much faster than an overhead crane. We custom design systems that integrate seamlessly with your workflow, helping you move bulky items safely and quickly.

Types of upenders

Upenders and tippers come in a wide variety based on the application. Green Valley Manufacturing custom manufactures your tipper or upender based on the application it will be used for.

Upender Types:

- Mold upender

- Coil Upender

- Die splitters

- And more