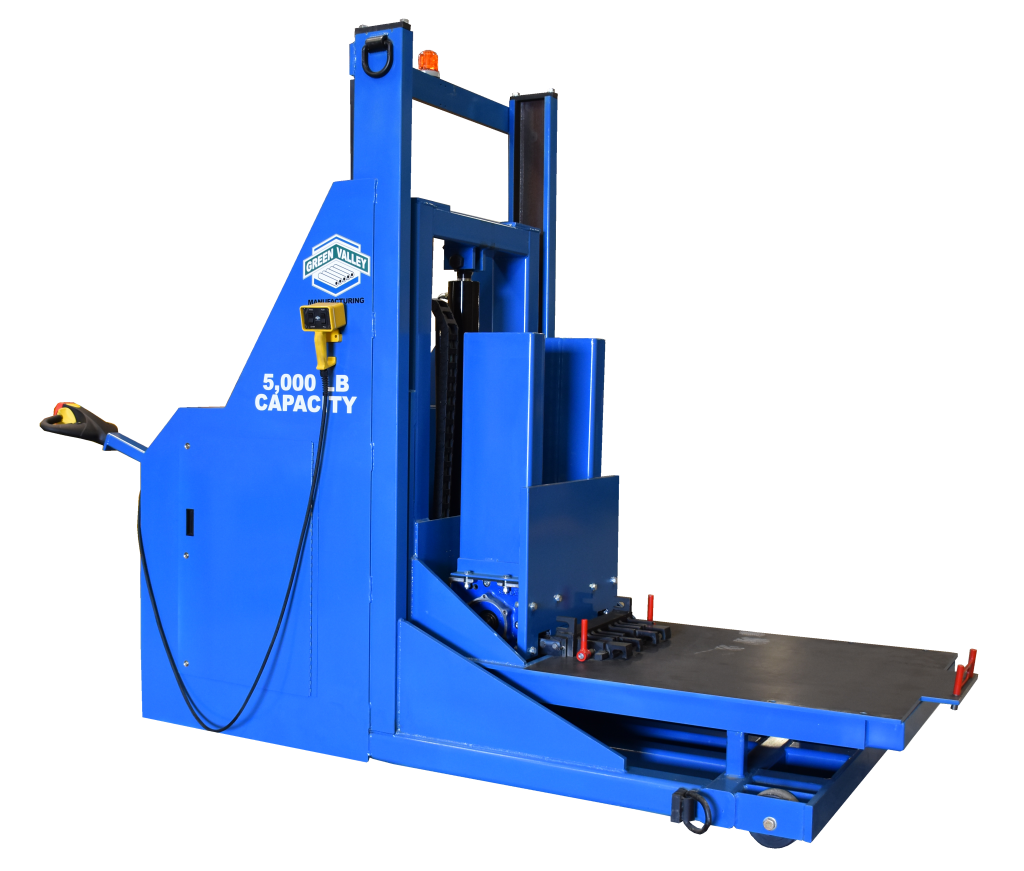

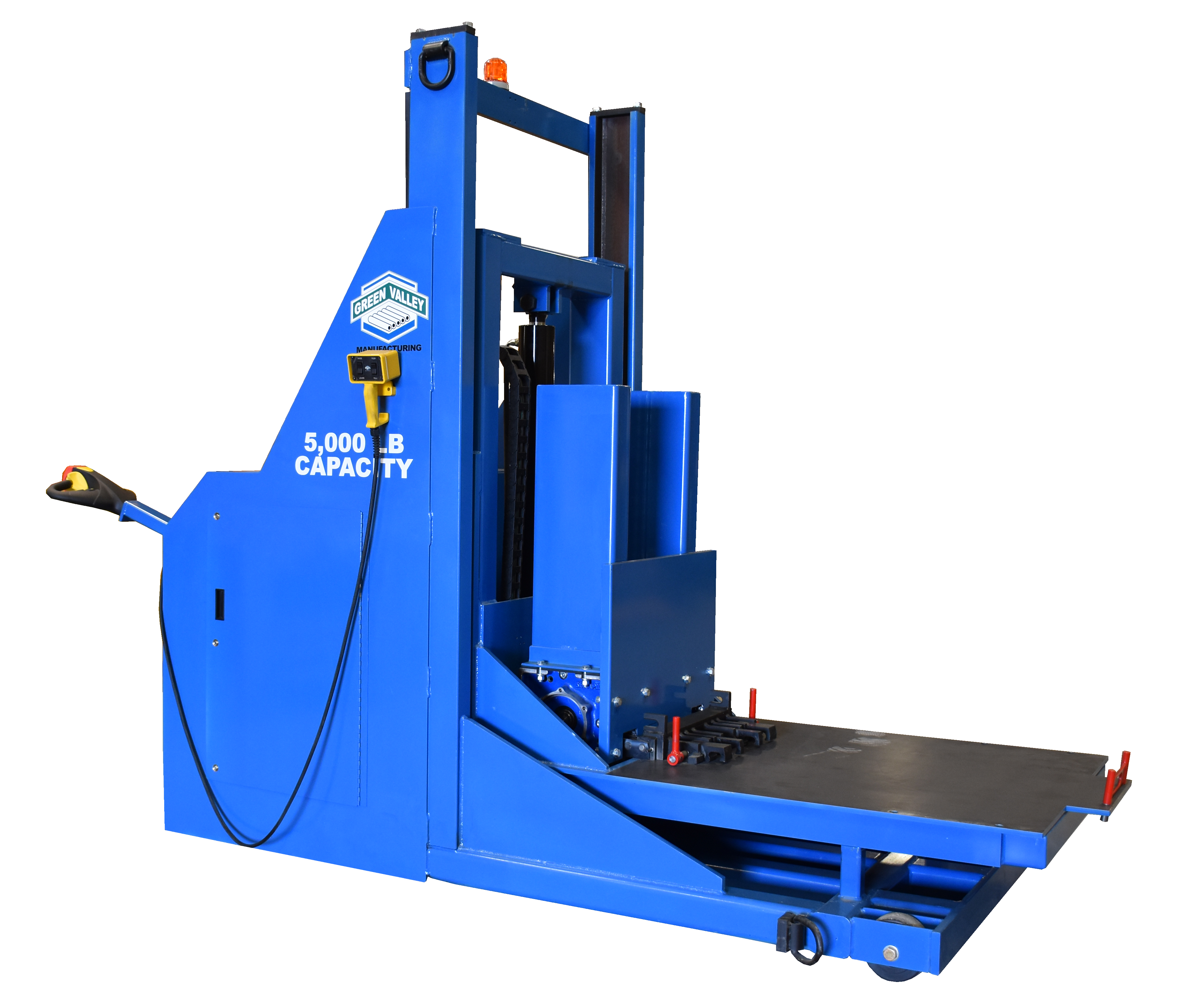

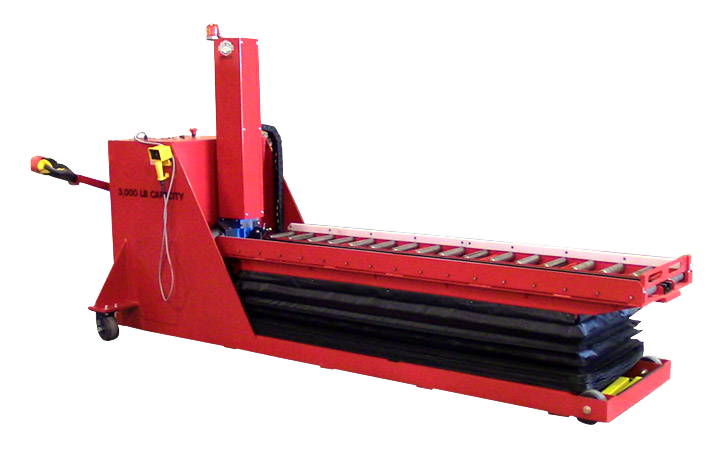

FEATURES

• Single station powered mold cart with variable height deck

• Powered push/pull system for mold transfers to/from presses and racks

• Powered drive via ergonomic tiller handle

• Dual rigid-chain push/pull system for single stroke powered mold transfers

• Heat shield between push/pull gripper and push/pull drive