FEATURES

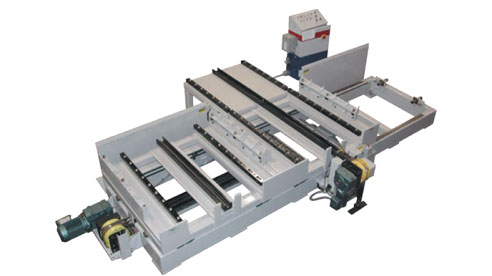

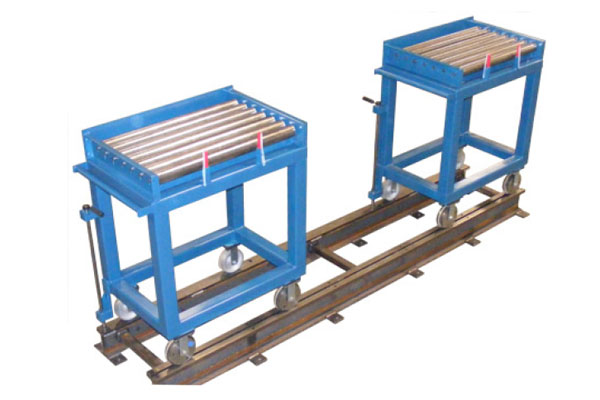

● 2-station die shuttle

● Fully guided die travel

● Power shuttle action

● Power die exchange

● Push button control

● Fork truck barriers at each side station

● Vertical guides for overhead loading of stations

GVMI, designers and builders of custom mold & die change systems, offers a full line of dedicated rail car systems. Mold and die changes are accomplished quickly & safely. As with all GVMI systems, customer needs are carefully considered and a system engineered specifically to meet

those needs. GVMI’s modular component philosophy delivers a high quality custom system at prices comparable to the one-size fits all competitors.

Contact a GVMI applications engineer today to discuss your requirements.