FEATURES

- Manually pushed overhead trolley system

- 72-position storage (4 high by 9 wide per side

- Powered lift for easy tool/pallet placement

- Drastically improved tool organization & retrieval times

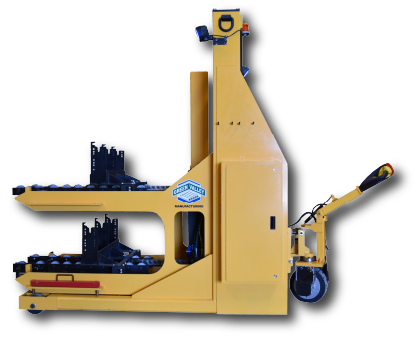

• Single station powered mold cart with variable height deck

• Powered push/pull system for mold transfers to/from presses and racks

• Powered drive via ergonomic tiller handle

• Dual rigid-chain push/pull system for single stroke powered mold transfers

• Heat shield between push/pull gripper and push/pull drive

Mold Cart:

• Powered push/pull with independent controls to move mold to/from press and racks

• UHMW decking on cart for low friction mold transfers

• Manual steering via tiller handle

• Docking rail locator cam rollers at base of cart

Mold Rack

• 4-wide X 2-high mold storage cells

• UHMW deck for low friction tool transfers

• Manual pins in sockets to retain load in its cell

• Bracket at each mold cell to accept mold cart docking lip on end of load deck

• Powered push/pull rigid chain system

• Powered Die Hook

• Powered Docking Features

• Powered Die Stops

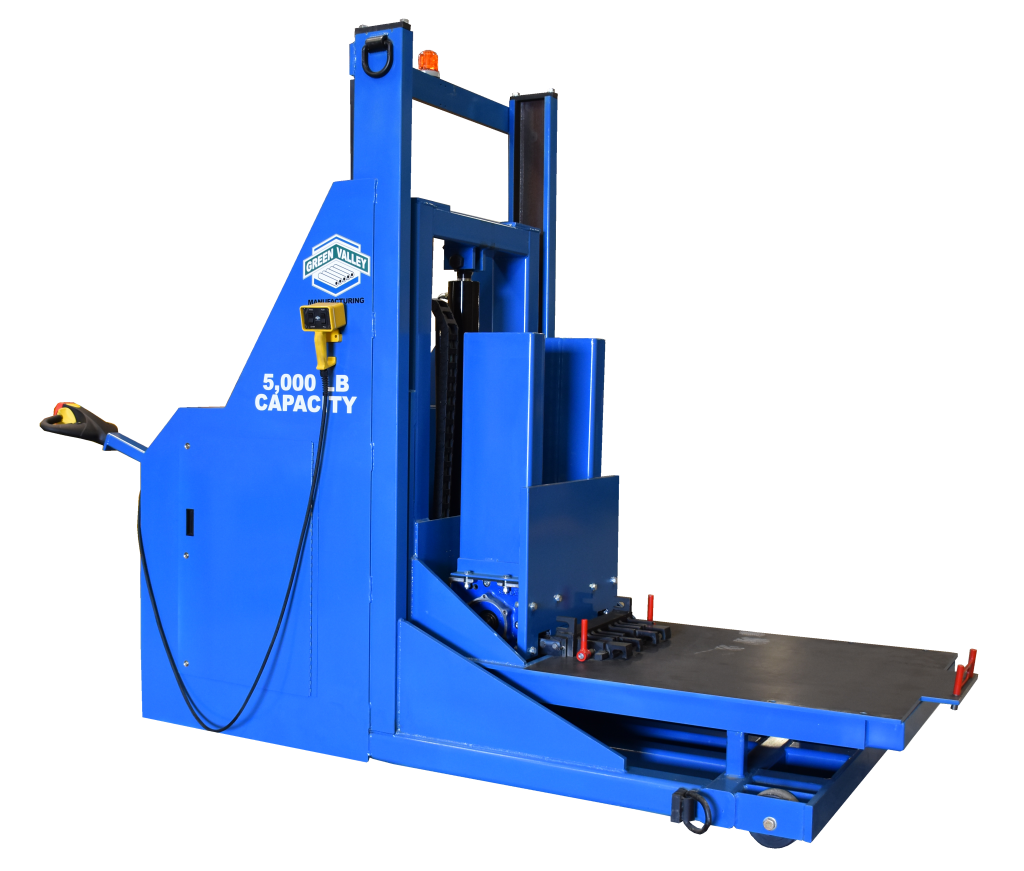

• Powered Lift

• Operator ride on station

• Dual camera system for docking visibility

•Operator ride-on station with safety cage

• Variable height load deck

• Dual ball screw push/pull with independent control

• Hydraulic mast lift system to raise deck

• Wired pendant for die transfer controls

• Deadman foot pedal to enable drive functions

• Front & rear blue lights

• CCTV camera & monitor for operator viewing

• Battery powered

• AC internal drives

• Audible alarm when unit is in motion

The extremely maneuverable unit featured is Green Valley’s 1,500 lb. capacity power driven mold/die changer. This is one of GV’s core units and is easily adaptable to meet different customer needs. With this changer, there are several styles and options from which to choose. This unit displays a configuration for Quick Die Change but is available in either quick mold or die change applications. All of Green Valley Mfg., Inc’s products are engineered to save time and money.

• Single station die cart

• High-temp gravity rollers for low friction tool transfers

• Powered wiper bar push/pull system

• Powered tiller drive

• Barrier with pins to engage sockets to retain die fully onboard