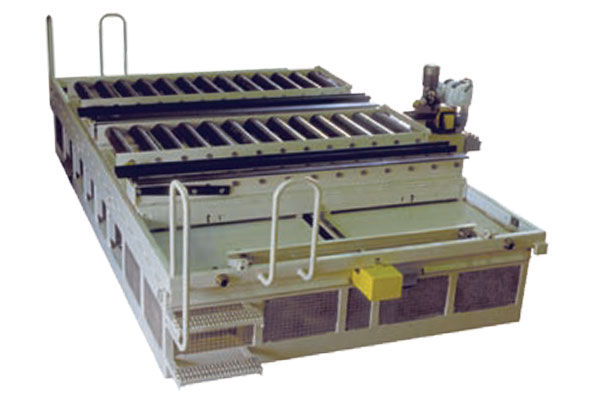

PRODUCT DESCRIPTION

Pictured is Green Valley Mfg. Inc.’s 2 x 80,000-lb dedicated quick change mold or die shuttle table system. The stationary unit provides tool prestaging at the press for rapid mold or die changing. This stand alone unit is capable of installing very large injection molding tools with great speed and accuracy. Mold turnarounds can be done in as little as 15 minutes.

FEATURES

● Air film shuttle system

● Serapid® insert/extract device

● Hydraulic powered shuttle

● Power mold/die hooks

● PLC control system management

● Hydraulic powered mold/die stops

● Hydraulic end of travel shock stops

● High capacity 3/4” wall roller bed

● Encoder monitored Serapid® position

● Variable frequency drive controlled insert/extract Serapid®

● Industrial controls in Nema 12 flange mount enclosure (on-board)

● Self contained hydraulic powered unit (on-board)

OPTIONS

● Deck configured for die change

● Adjustable height deck

● Mobile units with internal drives for moving tools to & from the press

● Additional automation

● Mechanical shuttle system

● Increased or decreased sizes and capacities

● Custom storage units

● Custom finishes