Quick Die/Mold Change Systems

2 X 40,000 lb. Die Press Transfer System (2619)

FEATURES

2 X 15,000 lb. Die Press Transfer System (2049)

FEATURES

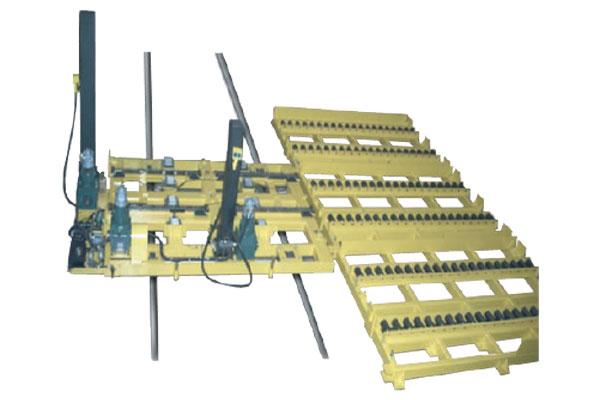

3 X 60,000 lb. Die Press Transfer System (1454)

FEATURES

16,000 lb. Die/Mold Press Transfer System (1005)

PRODUCT DESCRIPTION

FEATURES

OPTIONS

100,000 lb. Die/Mold Press Transfer System (1004)

PRODUCT DESCRIPTION

Configured for mold change, this unit was designed for high maneuverability. GV’s 2 x 50,000 lb. changer features air film technology and will rotate on its own axis. Dual internal drives provide tank type steering as well as straight line propulsion. Floor loading is very low, compared to wheeled units. This unit also features a 4-point ball screw lift deck for variable press height accommodations, roller slide guided push/pull device, and fully pneumatic power & controls. Extreme tool loads in limited spaces are this units specialty.

FEATURES

OPTIONS

2 X 3,000 lb. Die Shuttle (2821)

FEATURES

- Manual die shuttle

- Ergonomic push handle

- Manual location lock

- In-floor track

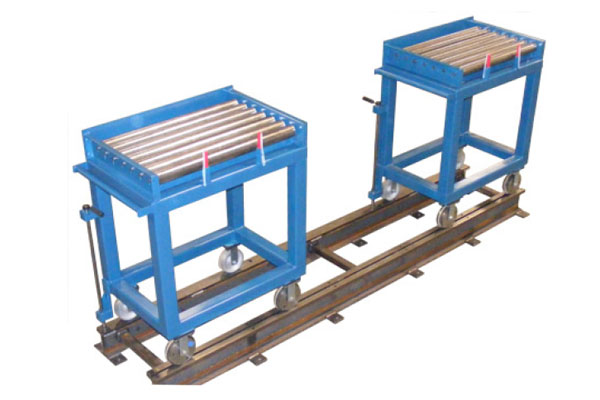

15,000 lb. Single Station Die Shuttle (1288)

PRODUCT DESCRIPTION

GVMI, designers and builders of custom mold & die change systems, offers a full line of dedicated rail car systems. Mold and die changes are accomplished quickly & safely. As with all GVMI systems, customer needs are carefully considered and a system engineered specifically to meet

those needs. GVMI’s modular component philosophy delivers a high quality custom system at prices comparable to the one-size fits all competitors.

Contact a GVMI applications engineer today to discuss your requirements.

FEATURES

- Designed for tools up to 48” F-B x 68” L-R x 38” H

- Fully pneumatic powered controls

- Dedicated rail car design

- 50” track gauge

-

Heavy duty hydraulic lift with accordion safety skirt enables variable height die transfer from 19” H min. to 55” H max

-

Power Serapid© insert/extract system with manual tool hook

- Power fail safe mold/die stops

-

Pneumatic powered car travel, 100 FPM, cyclo reducer, and chain final drive

- On-board pneumatic powered hydraulic unit

- On-board pneumatic hose reel

- Hand held pendant controls

- Safety bumpers, front & back

OPTIONS

- Capacities to 150,000 lbs

- Unit configuration for mold or die change

- Load capacity increased or decreased

- Increased size load deck

- Multiple station tool capacity (2 or 3 dies)

- Fixed deck height without lift

- Roller deck, powered or gravity

-

LP gas fueled internal combustion engine power

- AC electric power & controls

- Battery power & controls

- Powered insert/extract hook attachments

- Automation (per customer spec.)

- Operator ride-on unit

- Wireless remote control

- Custom finishes

-

Custom storage systems (mold or die racks)