FEATURES

- DC power

- On-board charger

- Variable height adjustment

- Powered push/pull

- Ride-on platform

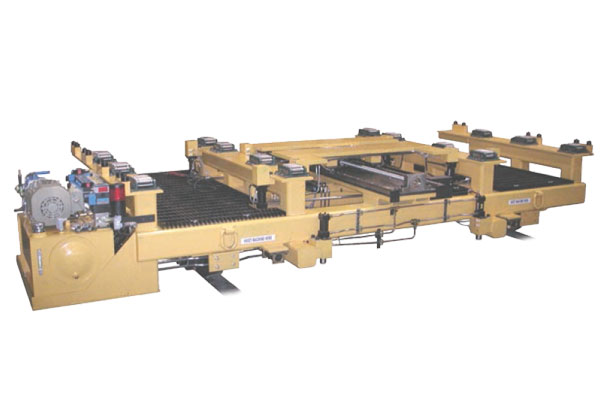

The rugged Titan 1293 is GV’s high capacity cart with an external tiller drive. Units may be customized for either mold or die tool changing.

Decks may be configured for 2 x 5,000 lb. tools for rapid tool change at press. Proven technology and quality components ensure years of service life. A wide variety of storage rack opt ions are also available. Let the custom engineering experts at Green Valley Mfg., Inc. design a system

tailored specifically to your requirements.

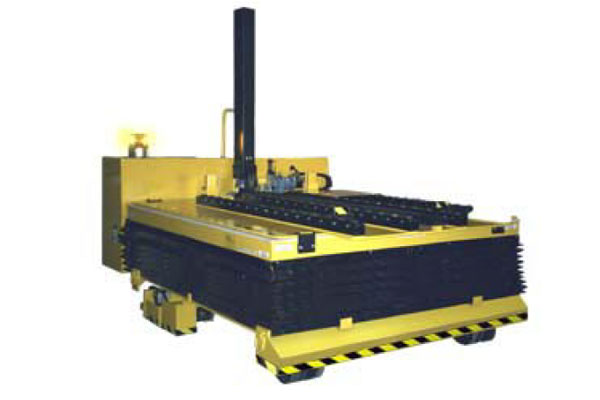

The Titan 1265 system provides users with a dependable tool changing source and storage. Proven technology as well as components make this system a valuable partner in solving your QDM and QMC needs. A fully self-contained battery powered drive, push/pull, and lift enhance operations. GV’s Titan 1265 is the manufacturer’s choice for efficient and dependable tool change. Call a GV application engineer for more details.