FEATURES

• Mold change speed: up to 10 FPM•

• Shuttle speed: 10-20 FPM

• Air supply: 250 SCFM @ 80 PSIG

• Electrical Requirements: 480VAC @ 30 AMPS

• PLC operator control panel

• Shuttle table is accurately positioned at each station

• Self-contained hydraulic pumping system

• Sub plate guide to align with stationary platen

• Differential encoder feedback on push/pull chain allows for positive positioning of mold hook.

• Hydraulically operated heavy-duty mold hook pin mounted to each chain drive. Feedback sensor on mold hook

• Hydraulic powered fail-safe mold stops for each station

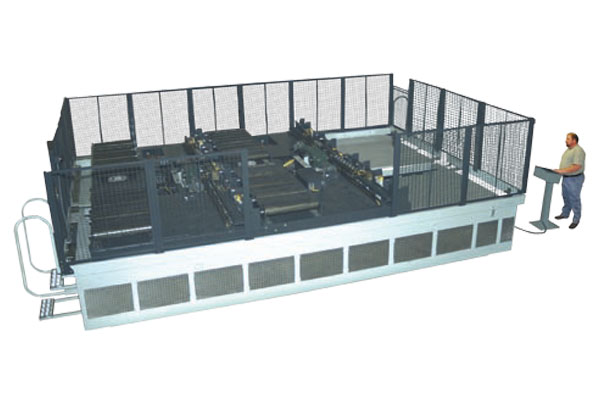

• Personnel access ladder end of the base table

• Structural tube air film shuttle platform with two mold change stations

• Heavy duty 5” DIA. X ¾ wall static roller bed with sealed cartridge type bearings

• Dual Serapid® insert/extract chain drives at each shuttle platform station

OPTIONS

● Dual press service available

● Full perimeter interlocked safety fencing